Home

Products

Physics research field

Type of experiment

Detector type

Behind the science

Tech in a nutshell

United Kingdom (EN)

Select your region or country.

Foundations of photodetection

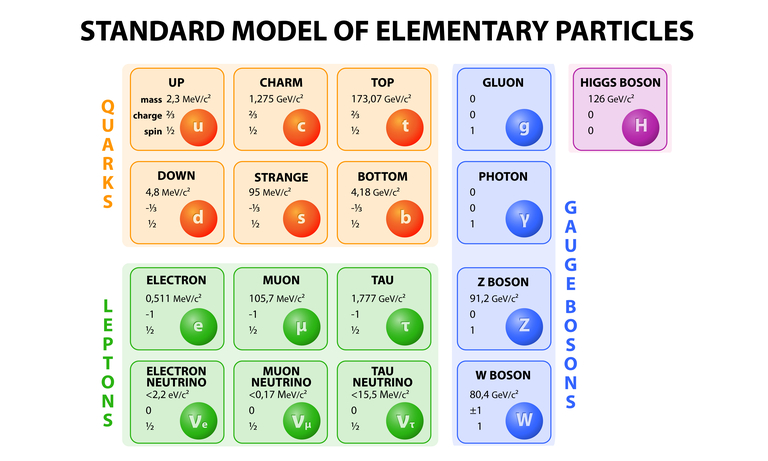

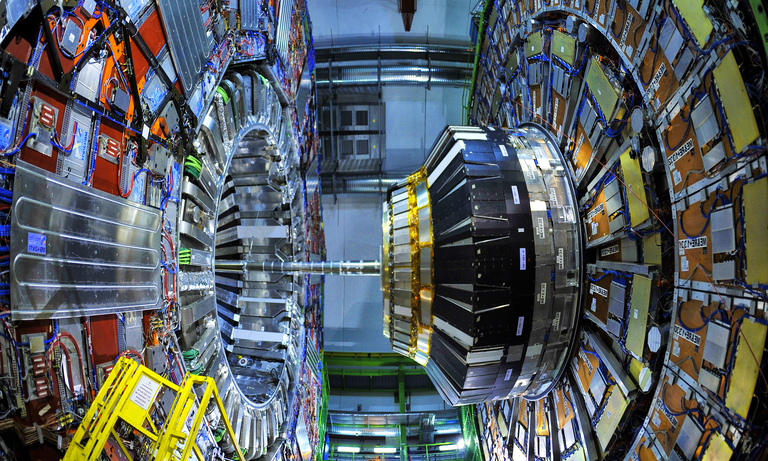

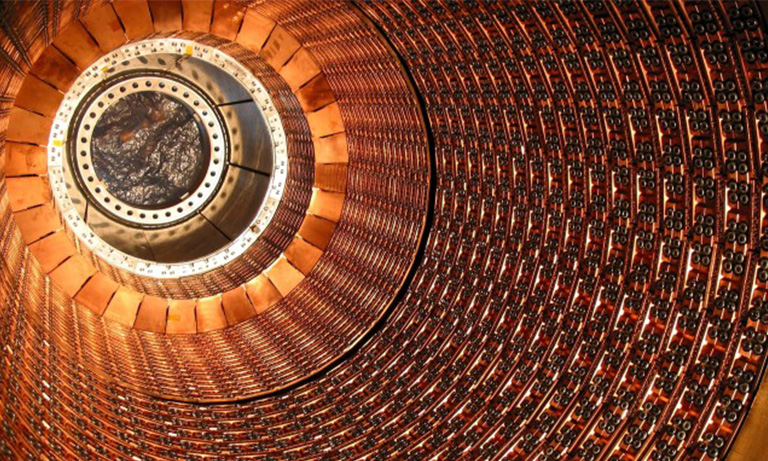

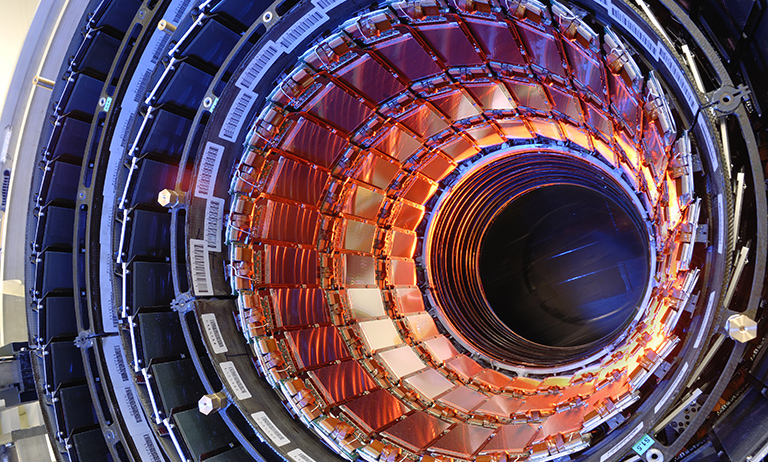

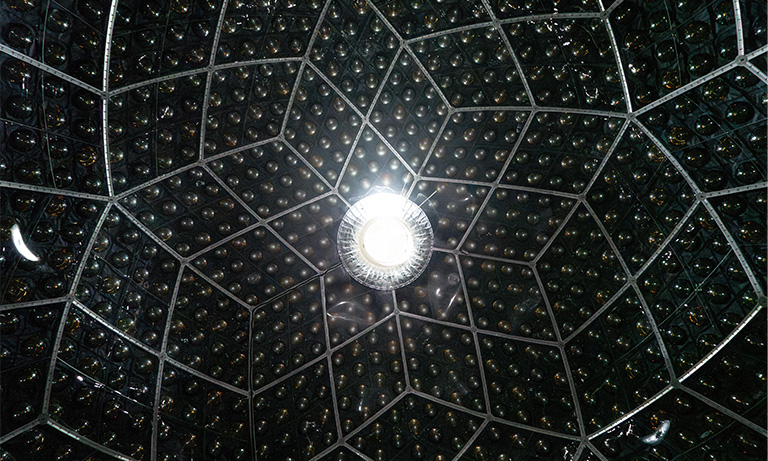

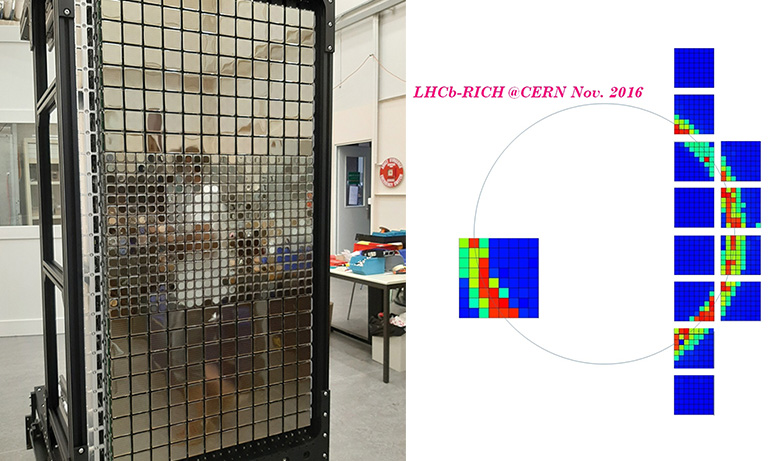

Photomultiplier Tubes (PMTs) have been a key photodetection technology for decades. Despite the advent of silicon photomultipliers (SiPMs), which offer advantages in certain applications, PMTs remain indispensable in scenarios requiring high speed, low noise, and high gain. Their continued relevance is shown by their critical role in neutrino physics experiments, such as Super-Kamiokande, where PMTs provide large photosensitive areas with minimal noise — an advantage over any alternative photodetectors.

Advantages of photomultiplier tubes

PMTs are known for their incredible versatility. Their adaptability arises from a wide range of available configurations, including various shapes, sizes, spectral response ranges, dynode structures, and readout methods. This allows them to be utilized in many applications ranging from medical devices to environmental monitors to particle physics experiments.

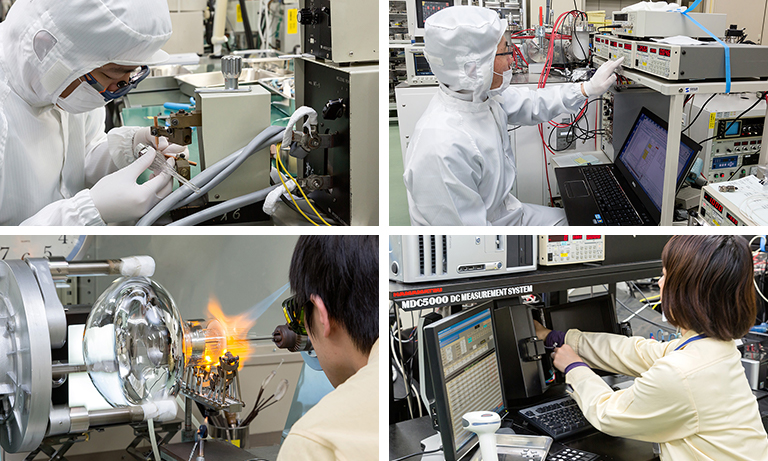

Hamamatsu Photonics has been manufacturing phototubes for over 70 years. During this time, the company has pushed the boundaries of light detection by enhancing PMT technology in key areas:

- Spectral response range: Devices sensitive from the vacuum ultraviolet (VUV) to the near-infrared (NIR) regions have been developed through the use of numerous photocathodes and window materials.

- Size: From compact, TO-8 package devices to 20” tubes, Hamamatsu offers PMTs with a photosensitive area in a shape and size to suit a variety of application requirements.

- Gain structure: Hamamatsu has developed PMTs with various gain structures, including classic dynodes (such as box-and-grid and circular-stage types), metal channels, microchannel plates (MCPs), and semiconductors (avalanche diodes). Each offers its own unique advantage to light detection.

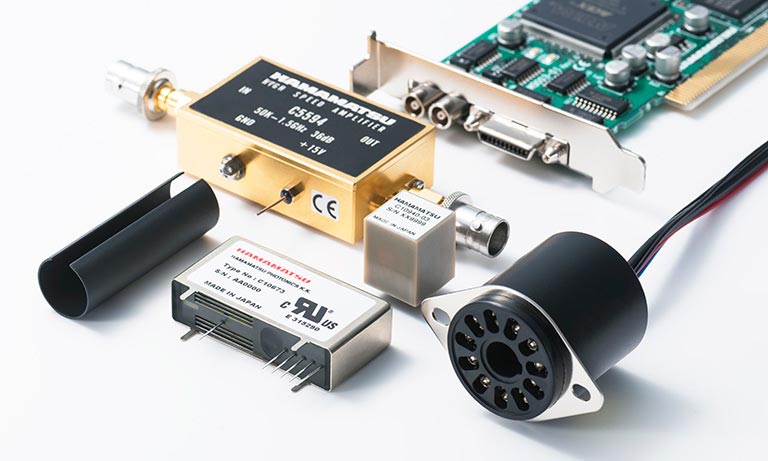

- Accessories: A suite of accessories, including high-voltage power supplies, housings, and plug-and-play modules, supports PMT integration into various systems.

Hamamatsu experts in the PMT manufacturing process. It can be done by hand so that even a single product can be tailored according to the request.

Hamamatsu’s experience and constant engagement in the research and development of PMT technology are the reasons that we continue to be the world-leading manufacturer of these devices.

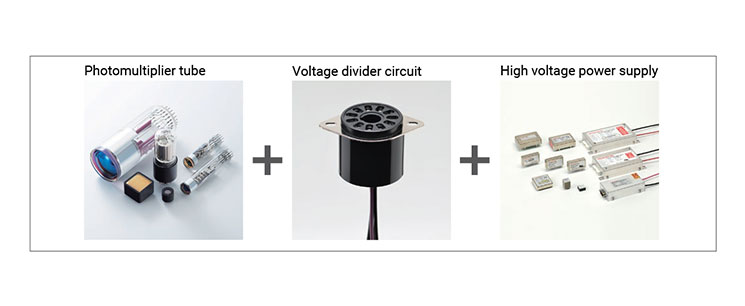

Essential components for PMT operation

At its core, a PMT consists of a vacuum tube with an input window and photocathode for light collection, a gain structure for the multiplication of the photoelectrons, and an anode to collect the photoelectrons generated. Several accessories enhance PMT functionality:

Key accessories

1) High Voltage Power Supply (HVPS):

- Required to achieve electron multiplication, a high voltage (typically between 500 and 2000 volts) across the gain structure (i.e., dynodes, metal channels, MCP, etc.).

- A stable HVPS is critical as the applied voltage affects the gain and signal output of the device.

- Hamamatsu offers several HVPS options, ranging from benchtop to board-level devices, with a variety of voltage outputs.

2) Amplifier:

- Converts high-impedance current signals from the PMT into low-impedance voltage signals.

- Hamamatsu amplifiers offer excellent output linearity and a range of bandwidths and current-to-voltage conversion factors.

3) Voltage divider circuits:

- Used with dynode structures to distribute HVPS output to each electrode.

- Hamamatsu provides socket assemblies with a built-in voltage divider circuit and optional socket assemblies that include an amplifier and/or HVPS:

i. D-type: built-in voltage divider circuit

ii. DA-type: built-in voltage divider circuit + amplifier

iii. DP-type: built-in voltage divider circuit + HVPS

iv. DAP-type: built-in voltage divider circuit + amplifier + HVPS

4) Thermoelectric coolers:

- Reduce thermal noise by lowering PMT temperature, improving the signal-to-noise ratio (SNR).

5) Magnetic shielding:

- Protects PMTs from external magnetic fields that can cause changes in the PMT output.

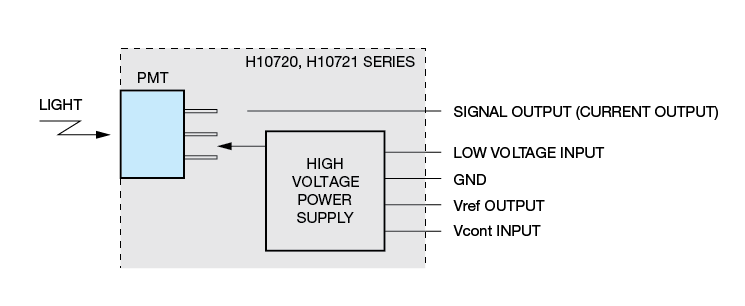

PMT Modules

PMT modules offer simple, “plug-and-play” PMT options. They integrate essential components such as the PMT, HVPS, and voltage divider circuit, requiring only a low-voltage input (e.g., 5 or 15 volts).

PMT composition

Fig.1: Block diagram of a photomultiplier module

Hamamatsu also offers modules with additional features:

- Voltage output modules: Include an integrated amplifier for easy signal processing.

- Photon counting heads: Include an integrated photon counting circuit, which produces a digital output signal. This signal can be measured by an external counter for photon counting measurements in very low-light-level applications.

- Gated PMT modules: Feature an electrical gate function (electronic shutter) for timed control over when the PMT is sensitive to light. These are useful for eliminating signals from excitation light or for high-speed time-resolved measurements.

- Cooler-integrated modules: Reduce noise and improve SNR.

Images of various PMT types

PMT accessories

Comparison of PMT technologies

While the standard PMT with dynode structures remains widely used, alternative designs such as Microchannel plate PMTs (MCP-PMTs) and hybrid photodetectors (HPDs) offer unique benefits:

| Key benefits | Main applications | More information | |

|---|---|---|---|

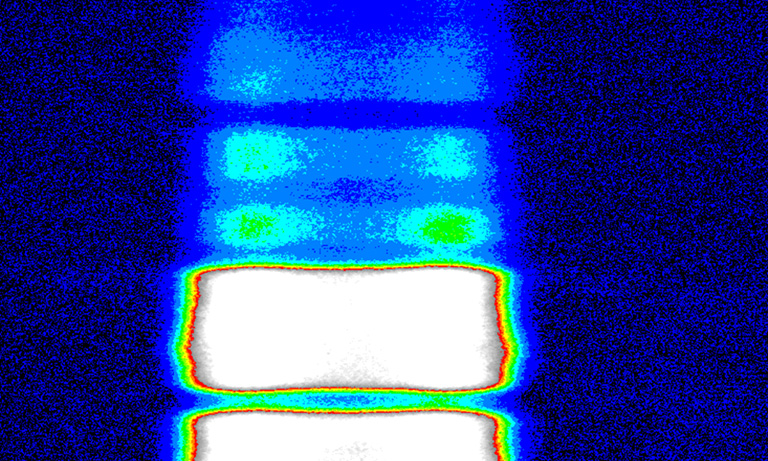

| MCP-PMTs | Utilize microchannel plates for electron multiplication, providing robustness in magnetic fields and superior timing response characteristics (rise time, fall time, transit time spread). | Particularly useful in calorimetry and time-of-flight (TOF) experiments. | Microchannel plate PMTs (MCP-PMT) |

| HPDs | Use a unique approach for signal amplification. They have a better S/N ratio in the case of very weak light detection. | Advantageous in laser microscopy, time-correlated single-photon counting (TCSPC), LiDAR, and High Energy Physics applications in general. | Hybrid photodetectors (HPDs) |

| PMTs | Retain superiority in specific applications. Custom solutions, though costly, will meet specialized needs. | Dark matter detection. Lower radioactivity value applications or oil-well logging (high-temperature PMTs). | Photomultiplier tubes (PMTs) |

Future directions

Hamamatsu is committed to advancing PMT technology to address emerging challenges and applications. Current development priorities include:

- Enhancing the lifetime characteristics of MCP-PMTs.

- Reducing operating voltages and expanding module options for HPDs.

By continually innovating and refining its products, Hamamatsu ensures PMTs remain at the forefront of photodetection technology, meeting the needs of both current and future applications.

Further readings and resources

Hamamatsu Photonics, Photomultiplier Tubes: Basics and Applications, 4th ed., Hamamatsu Photonics K.K., Japan, 2017. [Online]. Available: PMT_handbook_v4E.pdf

Hamamatsu Photonics, Photomultiplier Tubes and Assemblies for Scintillation counting & High Energy Physics, Hamamatsu Photonics K.K., Japan, 2024. [Online]. Available: PMT_TPMZ0003E.pdf

Hamamatsu Photonics, PMT Modules Selection Guide, Hamamatsu Photonics K.K., Japan, 2021. [Online]. Available: PMTmodules_TPMO1113E.pdf

- Confirmation

-

It looks like you're in the . If this is not your location, please select the correct region or country below.

You're headed to Hamamatsu Photonics website for GB (English). If you want to view an other country's site, the optimized information will be provided by selecting options below.

In order to use this website comfortably, we use cookies. For cookie details please see our cookie policy.

- Cookie Policy

-

This website or its third-party tools use cookies, which are necessary to its functioning and required to achieve the purposes illustrated in this cookie policy. By closing the cookie warning banner, scrolling the page, clicking a link or continuing to browse otherwise, you agree to the use of cookies.

Hamamatsu uses cookies in order to enhance your experience on our website and ensure that our website functions.

You can visit this page at any time to learn more about cookies, get the most up to date information on how we use cookies and manage your cookie settings. We will not use cookies for any purpose other than the ones stated, but please note that we reserve the right to update our cookies.

1. What are cookies?

For modern websites to work according to visitor’s expectations, they need to collect certain basic information about visitors. To do this, a site will create small text files which are placed on visitor’s devices (computer or mobile) - these files are known as cookies when you access a website. Cookies are used in order to make websites function and work efficiently. Cookies are uniquely assigned to each visitor and can only be read by a web server in the domain that issued the cookie to the visitor. Cookies cannot be used to run programs or deliver viruses to a visitor’s device.

Cookies do various jobs which make the visitor’s experience of the internet much smoother and more interactive. For instance, cookies are used to remember the visitor’s preferences on sites they visit often, to remember language preference and to help navigate between pages more efficiently. Much, though not all, of the data collected is anonymous, though some of it is designed to detect browsing patterns and approximate geographical location to improve the visitor experience.

Certain type of cookies may require the data subject’s consent before storing them on the computer.

2. What are the different types of cookies?

This website uses two types of cookies:

- First party cookies. For our website, the first party cookies are controlled and maintained by Hamamatsu. No other parties have access to these cookies.

- Third party cookies. These cookies are implemented by organizations outside Hamamatsu. We do not have access to the data in these cookies, but we use these cookies to improve the overall website experience.

3. How do we use cookies?

This website uses cookies for following purposes:

- Certain cookies are necessary for our website to function. These are strictly necessary cookies and are required to enable website access, support navigation or provide relevant content. These cookies direct you to the correct region or country, and support security and ecommerce. Strictly necessary cookies also enforce your privacy preferences. Without these strictly necessary cookies, much of our website will not function.

- Analytics cookies are used to track website usage. This data enables us to improve our website usability, performance and website administration. In our analytics cookies, we do not store any personal identifying information.

- Functionality cookies. These are used to recognize you when you return to our website. This enables us to personalize our content for you, greet you by name and remember your preferences (for example, your choice of language or region).

- These cookies record your visit to our website, the pages you have visited and the links you have followed. We will use this information to make our website and the advertising displayed on it more relevant to your interests. We may also share this information with third parties for this purpose.

Cookies help us help you. Through the use of cookies, we learn what is important to our visitors and we develop and enhance website content and functionality to support your experience. Much of our website can be accessed if cookies are disabled, however certain website functions may not work. And, we believe your current and future visits will be enhanced if cookies are enabled.

4. Which cookies do we use?

There are two ways to manage cookie preferences.

- You can set your cookie preferences on your device or in your browser.

- You can set your cookie preferences at the website level.

If you don’t want to receive cookies, you can modify your browser so that it notifies you when cookies are sent to it or you can refuse cookies altogether. You can also delete cookies that have already been set.

If you wish to restrict or block web browser cookies which are set on your device then you can do this through your browser settings; the Help function within your browser should tell you how. Alternatively, you may wish to visit www.aboutcookies.org, which contains comprehensive information on how to do this on a wide variety of desktop browsers.

5. What are Internet tags and how do we use them with cookies?

Occasionally, we may use internet tags (also known as action tags, single-pixel GIFs, clear GIFs, invisible GIFs and 1-by-1 GIFs) at this site and may deploy these tags/cookies through a third-party advertising partner or a web analytical service partner which may be located and store the respective information (including your IP-address) in a foreign country. These tags/cookies are placed on both online advertisements that bring users to this site and on different pages of this site. We use this technology to measure the visitors' responses to our sites and the effectiveness of our advertising campaigns (including how many times a page is opened and which information is consulted) as well as to evaluate your use of this website. The third-party partner or the web analytical service partner may be able to collect data about visitors to our and other sites because of these internet tags/cookies, may compose reports regarding the website’s activity for us and may provide further services which are related to the use of the website and the internet. They may provide such information to other parties if there is a legal requirement that they do so, or if they hire the other parties to process information on their behalf.

If you would like more information about web tags and cookies associated with on-line advertising or to opt-out of third-party collection of this information, please visit the Network Advertising Initiative website http://www.networkadvertising.org.

6. Analytics and Advertisement Cookies

We use third-party cookies (such as Google Analytics) to track visitors on our website, to get reports about how visitors use the website and to inform, optimize and serve ads based on someone's past visits to our website.

You may opt-out of Google Analytics cookies by the websites provided by Google:

https://tools.google.com/dlpage/gaoptout?hl=en

As provided in this Privacy Policy (Article 5), you can learn more about opt-out cookies by the website provided by Network Advertising Initiative:

http://www.networkadvertising.org

We inform you that in such case you will not be able to wholly use all functions of our website.

Close