Home

Products

Physics Research Field

Type of Experiment

Detector Type

Behind the Science

Tech in a Nutshell

United Kingdom (EN)

Select your region or country.

KM3NeT: Deep under the Mediterranean Sea

© Courtesy KM3NeT; Artist’s impression of the KM3NeT detector with the multi-PMT optical module

A scientific mystery

Deep down in the darkness of the Mediterranean Sea stand hundreds of mysterious vertical strings, each carrying large spherical glass frames stretching far into the distance.

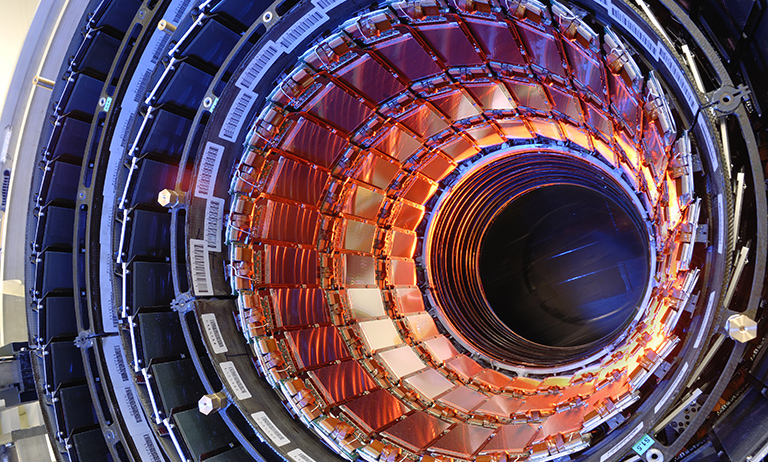

This improbable infrastructure is built at 3,500 m below the waves and covers a cubic kilometer of seawater. Such an undertaking can only be driven by the pursuit of something equally as extraordinary: understanding the beginning of our universe through the observation of neutrinos.

Neutrinos are incredibly difficult to observe due to their elusive nature. Their weak interaction plays a crucial role in our learning of how matter evolved from simple particles into more complex composites, creating the world we live in. Only in the darkness nearing the seabed can detectors capture the faintest amount of light from neutrinos striking the water molecules.

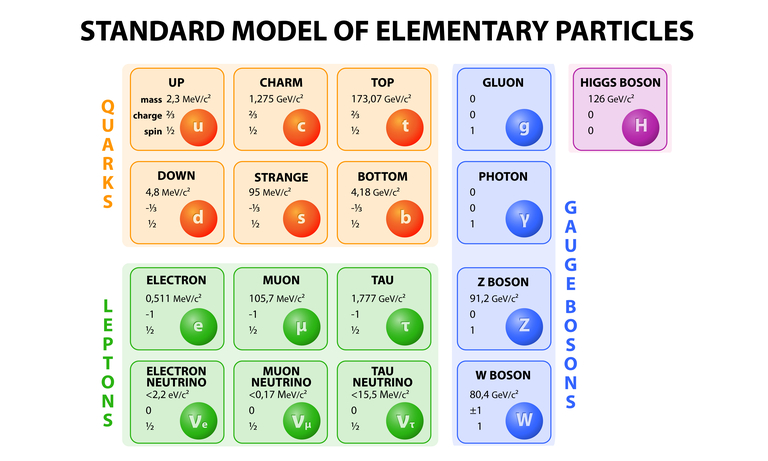

The European research infrastructure KM3NeT houses the next generation of neutrino telescopes underwater. Named after its instrumented cubic kilometer volume, institutions from across the world are collaborating in the development of these neutrino studies. Their first objective is the discovery and subsequent observation of high-energy neutrino sources in the Universe; their second is the determination of the mass hierarchy of neutrinos1.

Faced with the difficulty of observing these subatomic particles and the titanic technical challenge of their research environment, only incredibly sophisticated technology can successfully shine a light on this scientific mystery.

© Courtesy KM3NeT; Deployment of a prototype launching vehicle

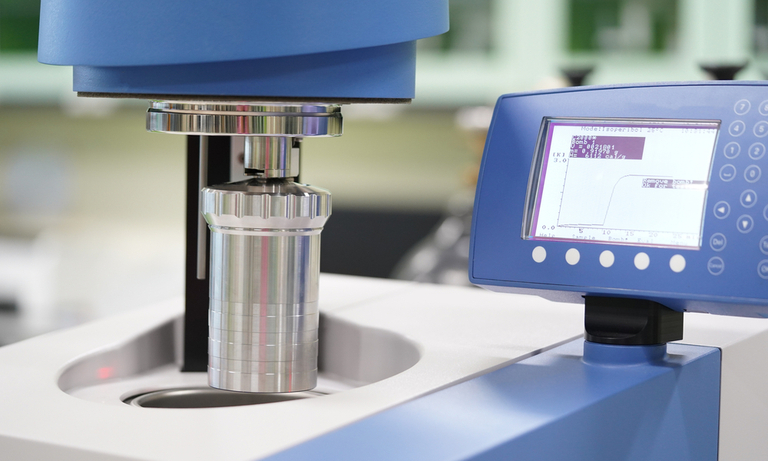

Photomultiplier tubes (PMTs) - product lineup

An enormous endeavor

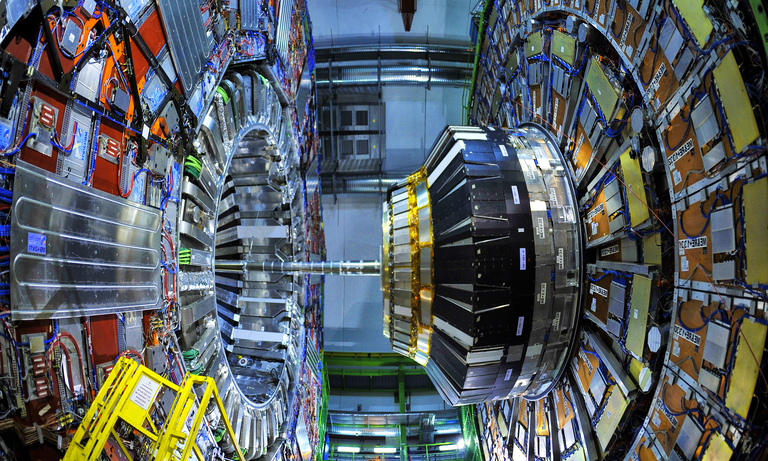

KM3NeT is an exceptionally intricate submarine operation. Not only does it require a large panel of skills and expertise to build such an infrastructure, but the right technology is crucial to its success. One of the key technologies is the detectors used for capturing the faint level of light indicating the neutrino interaction. This information is then transferred back to the data centers for scientific analysis.

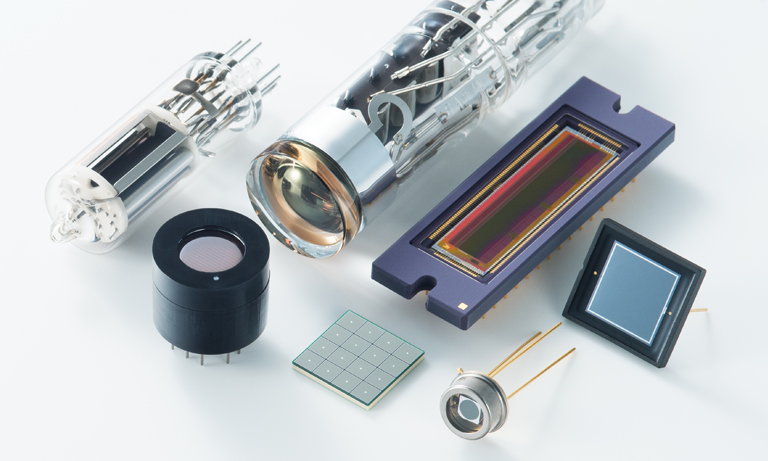

These ultra-fast photosensors are known as photomultiplier tubes (PMTs). As one of the world's leading manufacturers of PMTs, Hamamatsu Photonics was approached to participate in this venture. However, this was no small challenge.

The solution needed to be cost-effective, with a good response time, and provide a wide energy range, high-energy resolution, high sensitivity, and low noise. As neutrinos pass through matter as though it is not there, increasing the number of detectors meant increasing the chances of catching a neutrino interaction. At first, the idea of using a large-sized PMT made sense especially as Hamamatsu is known for offering the world's largest PMT (20 inches). However, the KM3NeT Collaboration thought of a more efficient design: large glass spheres called Digital Optical Modules, which included 31 PMTs of only 3 inches. This was the ideal cost-effective and highly performant solution as the PMTs were smaller, and easier to produce yet their spatial resolution was greater given the quantity. However, this meant that around 192,000 of these 3-inch PMTs were needed.

The challenge faced by Hamamatsu Photonics was to produce this large quantity of PMTs while maintaining a high level of quality and repeatability. PMTs are made of glass and are often even handmade; their production is not automated like other products, so realizing thousands at such high standards in a short timeframe was an enormous endeavor.

© Courtesy KM3NeT; Digital Optical Module

A new era

Thankfully, Hamamatsu Photonics already had experience working with many of the world’s leading neutrino observation projects, including the University of Tokyo’s Super-Kamiokande in Japan. Although this was a tough task, the Hamamatsu spirit never wavered.

To meet the research institutes’ demands, Hamamatsu decided to invest in doubling its manufacturing capacity. This major enterprise led them to produce much higher volumes of PMTs managed not only through an increase in the factory workforce but also through the introduction of a much more complex logistical network.

Hamamatsu manufacturing experts also achieved remarkable consistency in the manufacture of PMTs through non-stop repeatable production, which still goes on to this day. In-house testing complemented this approach and ensured the best possible quality of sensors – crucial for the accuracy of the data studied. So far, Hamamatsu has already delivered all the PMTs which are needed to integrate more than 2,000 DOMs, enough for putting together more than 100 detection strings.

Since the start of this adventure in December 20152 arrays of thousands of these optical sensors have been working relentlessly to capture the faint light in the deep sea. Yet KM3NeT is only just getting started, more infrastructures are already being built, meaning even more collected data, aiming at building the largest detector of neutrinos in the Northern Hemisphere.

“Most telescopes look upwards at the light coming from the sky. The KM3NeT telescope searches for neutrinos and prefers to look downwards through the Earth to study the austral sky.” from Dr. Paschal Coyle, Spokesperson of KM3NeT Collaboration.

Latest news

February 12, 2025

The KM3NeT Collaboration has revealed the observation of a cosmic neutrino with an unprecedented energy level of around 220 PeV, a breakthrough that we are proud to support.

Related products & information

- Confirmation

-

It looks like you're in the . If this is not your location, please select the correct region or country below.

You're headed to Hamamatsu Photonics website for GB (English). If you want to view an other country's site, the optimized information will be provided by selecting options below.

In order to use this website comfortably, we use cookies. For cookie details please see our cookie policy.

- Cookie Policy

-

This website or its third-party tools use cookies, which are necessary to its functioning and required to achieve the purposes illustrated in this cookie policy. By closing the cookie warning banner, scrolling the page, clicking a link or continuing to browse otherwise, you agree to the use of cookies.

Hamamatsu uses cookies in order to enhance your experience on our website and ensure that our website functions.

You can visit this page at any time to learn more about cookies, get the most up to date information on how we use cookies and manage your cookie settings. We will not use cookies for any purpose other than the ones stated, but please note that we reserve the right to update our cookies.

1. What are cookies?

For modern websites to work according to visitor’s expectations, they need to collect certain basic information about visitors. To do this, a site will create small text files which are placed on visitor’s devices (computer or mobile) - these files are known as cookies when you access a website. Cookies are used in order to make websites function and work efficiently. Cookies are uniquely assigned to each visitor and can only be read by a web server in the domain that issued the cookie to the visitor. Cookies cannot be used to run programs or deliver viruses to a visitor’s device.

Cookies do various jobs which make the visitor’s experience of the internet much smoother and more interactive. For instance, cookies are used to remember the visitor’s preferences on sites they visit often, to remember language preference and to help navigate between pages more efficiently. Much, though not all, of the data collected is anonymous, though some of it is designed to detect browsing patterns and approximate geographical location to improve the visitor experience.

Certain type of cookies may require the data subject’s consent before storing them on the computer.

2. What are the different types of cookies?

This website uses two types of cookies:

- First party cookies. For our website, the first party cookies are controlled and maintained by Hamamatsu. No other parties have access to these cookies.

- Third party cookies. These cookies are implemented by organizations outside Hamamatsu. We do not have access to the data in these cookies, but we use these cookies to improve the overall website experience.

3. How do we use cookies?

This website uses cookies for following purposes:

- Certain cookies are necessary for our website to function. These are strictly necessary cookies and are required to enable website access, support navigation or provide relevant content. These cookies direct you to the correct region or country, and support security and ecommerce. Strictly necessary cookies also enforce your privacy preferences. Without these strictly necessary cookies, much of our website will not function.

- Analytics cookies are used to track website usage. This data enables us to improve our website usability, performance and website administration. In our analytics cookies, we do not store any personal identifying information.

- Functionality cookies. These are used to recognize you when you return to our website. This enables us to personalize our content for you, greet you by name and remember your preferences (for example, your choice of language or region).

- These cookies record your visit to our website, the pages you have visited and the links you have followed. We will use this information to make our website and the advertising displayed on it more relevant to your interests. We may also share this information with third parties for this purpose.

Cookies help us help you. Through the use of cookies, we learn what is important to our visitors and we develop and enhance website content and functionality to support your experience. Much of our website can be accessed if cookies are disabled, however certain website functions may not work. And, we believe your current and future visits will be enhanced if cookies are enabled.

4. Which cookies do we use?

There are two ways to manage cookie preferences.

- You can set your cookie preferences on your device or in your browser.

- You can set your cookie preferences at the website level.

If you don’t want to receive cookies, you can modify your browser so that it notifies you when cookies are sent to it or you can refuse cookies altogether. You can also delete cookies that have already been set.

If you wish to restrict or block web browser cookies which are set on your device then you can do this through your browser settings; the Help function within your browser should tell you how. Alternatively, you may wish to visit www.aboutcookies.org, which contains comprehensive information on how to do this on a wide variety of desktop browsers.

5. What are Internet tags and how do we use them with cookies?

Occasionally, we may use internet tags (also known as action tags, single-pixel GIFs, clear GIFs, invisible GIFs and 1-by-1 GIFs) at this site and may deploy these tags/cookies through a third-party advertising partner or a web analytical service partner which may be located and store the respective information (including your IP-address) in a foreign country. These tags/cookies are placed on both online advertisements that bring users to this site and on different pages of this site. We use this technology to measure the visitors' responses to our sites and the effectiveness of our advertising campaigns (including how many times a page is opened and which information is consulted) as well as to evaluate your use of this website. The third-party partner or the web analytical service partner may be able to collect data about visitors to our and other sites because of these internet tags/cookies, may compose reports regarding the website’s activity for us and may provide further services which are related to the use of the website and the internet. They may provide such information to other parties if there is a legal requirement that they do so, or if they hire the other parties to process information on their behalf.

If you would like more information about web tags and cookies associated with on-line advertising or to opt-out of third-party collection of this information, please visit the Network Advertising Initiative website http://www.networkadvertising.org.

6. Analytics and Advertisement Cookies

We use third-party cookies (such as Google Analytics) to track visitors on our website, to get reports about how visitors use the website and to inform, optimize and serve ads based on someone's past visits to our website.

You may opt-out of Google Analytics cookies by the websites provided by Google:

https://tools.google.com/dlpage/gaoptout?hl=en

As provided in this Privacy Policy (Article 5), you can learn more about opt-out cookies by the website provided by Network Advertising Initiative:

http://www.networkadvertising.org

We inform you that in such case you will not be able to wholly use all functions of our website.

Close